Handling

Handling and storage

For the correct handling of the pallets, a fork lift truck must be used, at least 2.5 m long, with the forks positioned in the maximum width position. Under normal conditions, the forks are positioned in the middle of the long side of the pallet, as they must grip the whole depth of the pallet. To allow the extraction of the slabs easily and safely, it is recommended to position the pallets in a suitable area where the lift truck can be moved around all sides of the pallet.

Instruments required

The instruments for lifting and handling the slabs can be chosen according to the size of the slab and the activities to be performed on the site, in particular:

– Fork lift truck with forks 2.5 m long;

– Frame with suction cups for handling large format slabs;

– Double suction cups for handling slabs with format up to 150×75 cm.

Cutting and Holes

Easy to work with

Maxfine can be easily processed by using some simple tools. It is recommended to process the slabs on a flat work surface, at least 5 cm longer than the slab from each side or double suction cup. It is recommended to perform the cutting operations with at least two operators. One operator is sufficient for making the holes.

Instruments required

Depending on the type of cut and process to be applied to the slab, the recommended types of tools are listed below:

– Handling frame with suction cups or double suction cups;

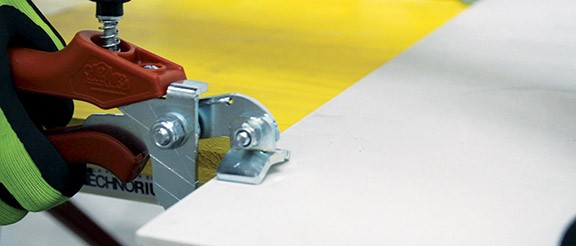

– Cutting guide with cutting carriage for linear cuts of 150/300 cm;

– Cutting pliers;

– Wet core bits;

– Angle grinder with diamond blade;

– Diamond buffer.

Traditional Floor Laying

Description and technical features

Maxfine requires the adhesive to be applied both on the setting bed and on the back of the slab. Maxfine slabs for flooring require the following conditions:

– A flat surface;

– Clean and free from dust, scraps and any lumps of cement;

– The setting bed must be uniform and have already undergone the drying shrinkage process;

– Repair of any cracks;

– Any uneven parts on the surface must be filled with suitable levelling compounds.

Instruments required:

– Cement-based powder adhesive for full spread, class “C2E according to EN12004 and S1 according to EN12002 standards”;

– 3×3 mm square toothed trowel and 15 mm round toothed trowel;

– Frame with suction cups for handling or double suction cups;

– Non-bounce plastic mallet 170×370 mm;

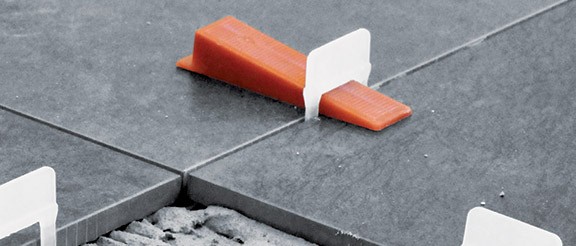

– Levelling system: base clip + wedge + pliers.

Traditional Floor Laying

Laying System

The laying system with hidden mechanical safety hook on 6 mm Maxfine slabs allows the wall covering to be installed in complete safety with a great impact.

For this application system, the Maxfine slab is pre-processed in the factory, so that it is delivered to the site already equipped with the hidden mechanical safety hook, sealed onto the back of the slab and complete with protective film on the back.

Instruments required

– Handling frame with suction cups;

– Cement-based powder adhesive for full spread, class “C2E according to EN12004 and S1 according to EN12002 standards”;

– 15 mm round toothed trowel;

– 3×3 mm square toothed trowel;

– Gas-powered nailing machine and relative nails.

Wall Covering

General Recommendations

For commercial and heavily used surface areas such as airports, hospitals, supermarkets, and any public spaces with heavy foot traffic which are thus subject to considerable soiling, it is necessary to use automatic cleaning machines with suction of the washing liquids.

This allows not only deep cleaning, but also the continuous removal of liquids containing substances that cause soiling, thus preventing the formation of films which are very difficult to remove. Any detergent on the market can be used in the desired concentration for cleaning the high technology sinterized FMG products, with the exception of HYDROFLUORIC acid (HF) or its compounds, according to UNI-EN 176 standards. After the floor is laid it is necessary to make a very accurate initial cleaning with proper products

Maintenance and care

Thanks to the characteristics of the production process the surface of FMG material is waterproof (the water absorption is minimum). Therefore the dirt cannot penetrate but it is necessary to remove it from the surface.

For this procedure do not use detergents containing waxes or waxing products, in order to avoid the forming of greasy layers; After the installation of floors, particularly of those made with polished materials, the surfaces should be adequately protected with particle board or other suitable materials in order to protect them from dirt and on-site processing.

For choosing the most appropriate detergent refer to the section Clean and Maintenance.